ACK Corporation

As a result of GEL’s work, ACK Corporation was able to increase production by 20% and reduce costs by 15%. The company’s inventory levels were also reduced by 10%, which freed up capital for other investments

Industry

Manufacturing

Challenge

ACK Corporation was struggling to keep up with demand for its products. Its production process was inefficient and outdated, and its inventory management system was a mess.

Solution

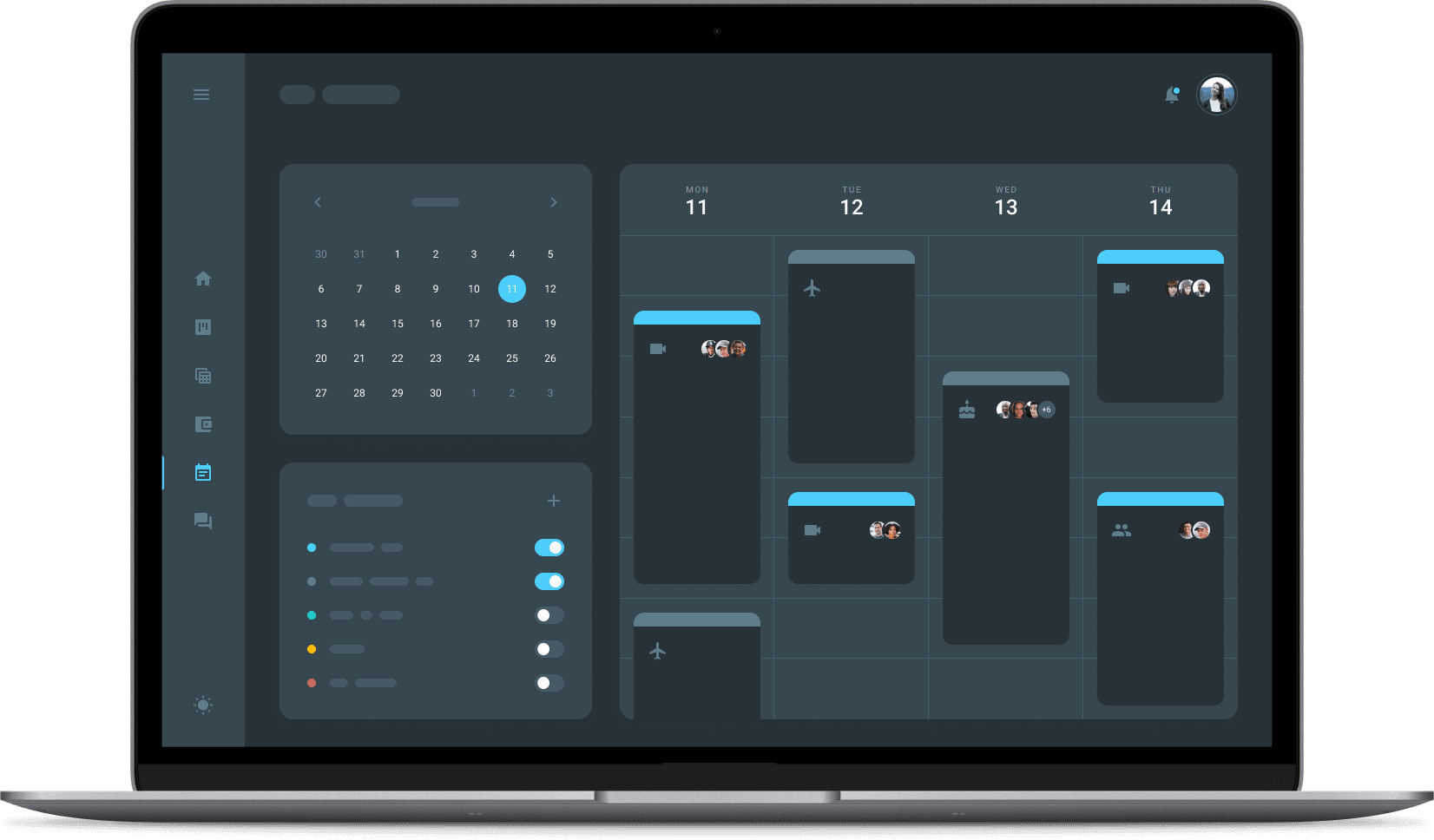

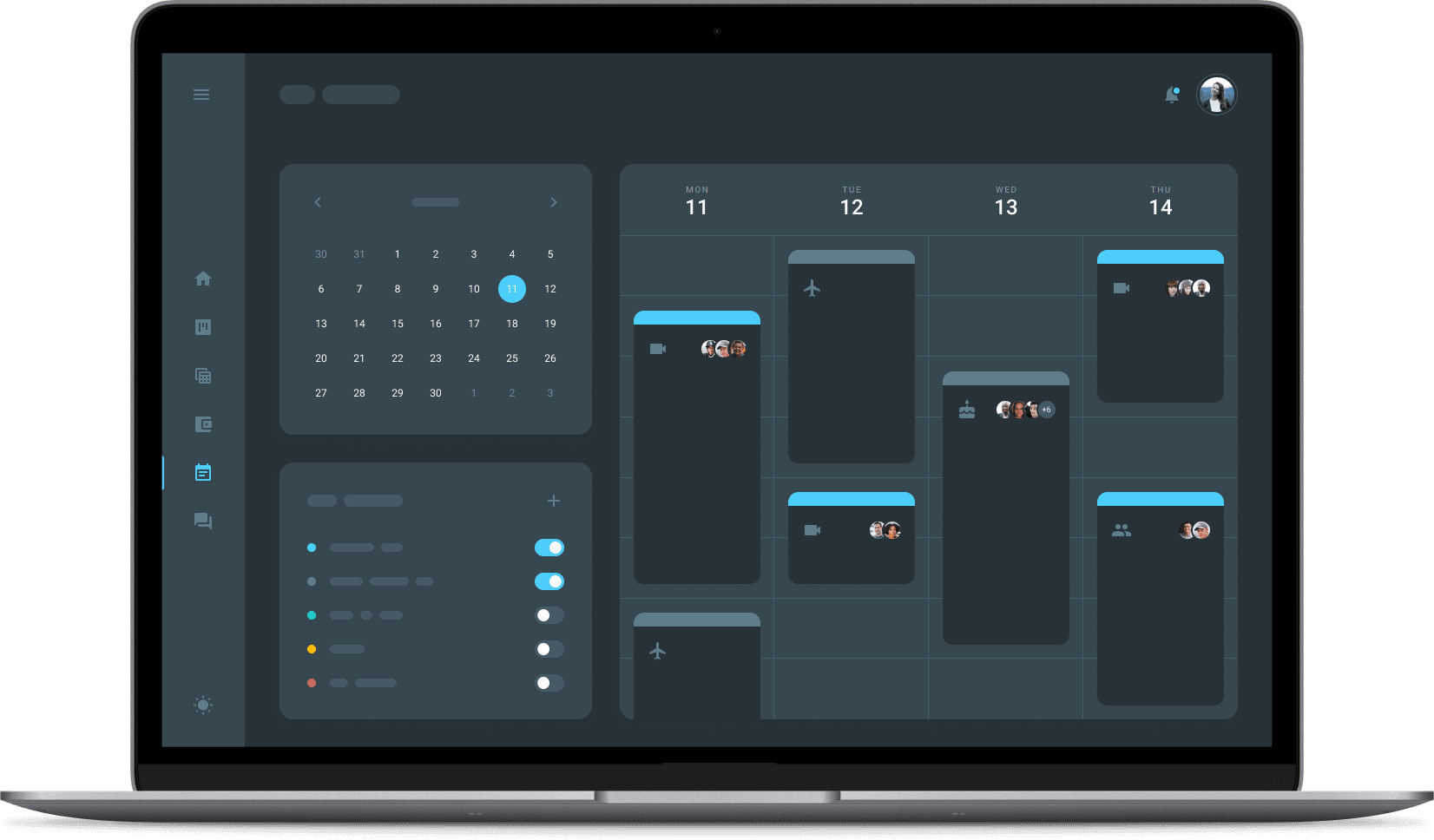

Great Expert Labs (GEL) designed and implemented a new production process for ACK Corporation that was more efficient and cost-effective. The team also developed a new inventory management system that helped ACK to better track its inventory levels and reduce waste.

Technology Used

Results

GEL used a variety of technologies to improve ACK Corporation’s manufacturing operations. The team used IoT sensors to track the movement of materials and products throughout the production process. This data was used to identify bottlenecks and areas for improvement. GEL also used AI to develop a new inventory management system that could predict demand and optimize inventory levels. Finally, GEL used cloud computing to deploy the new production process and inventory management system. This made it easy for ACK to scale its operations and access the system from anywhere in the world.

As a result of GEL’s work, ACK Corporation was able to increase production by 20% and reduce costs by 15%. The company’s inventory levels were also reduced by 10%, which freed up capital for other investments.

ACK Corporation is now able to meet the growing demand for its products and provide better service to its customers. The company is also more competitive in the global market.

Detailed Case Study

ACK Corporation is a leading manufacturer of widgets. The company was founded in 1950 and has grown to become one of the largest widget manufacturers in the world. ACK’s products are used in a variety of industries, including automotive, aerospace, and electronics.

In recent years, ACK Corporation has been facing a number of challenges. The company’s production process was inefficient and outdated. This was leading to high costs and long lead times. ACK’s inventory management system was also a mess. The company was carrying too much inventory, which was tying up capital and increasing costs.

ACK Corporation decided to partner with Great Expert Labs (GEL) to improve its manufacturing operations. GEL designed and implemented a new production process for ACK Corporation that was more efficient and cost-effective. The team also developed a new Inventory management system that helped ACK to better track its inventory levels and reduce waste.

We were very impressed with GEL’s expertise and professionalism. The team was able to quickly understand our challenges and develop a solution that met our needs. We are confident that our partnership with GEL will help us to achieve our business goals

VP of Manufacturing, ACK CorporationConclusion

ACK Corporation is a prime example of how technology can be used to improve manufacturing operations. By working with Great Expert Labs, ACK was able to implement a new production process and inventory management system that made the company more efficient and cost-effective. As a result, ACK is now able to meet the growing demand for its products and provide better service to its customers.

GEL helped us to transform our manufacturing operations. The new production process and inventory management system have made us more efficient and cost-effective. We are now able to meet the growing demand for our products and provide better service to our customers

CEO, ACK Corporation